TRBH VENTILATION SYSTEM

Informations

Code: TRBH

Type inputs: 4 Pt100

Outputs: 4 relays + RS485 or Ethernet

Plus: SMART ventilation system patented

| 中文 |

|

MANUAL NT935BH-D ENG.pdf |

|

MANUAL NT935BH ETH ENG.pdf |

|

MANUAL TRBH SYSTEM ENG.pdf |

|

Datasheet TRBH ITA-ENG.pdf |

“SMART” VENTILATION SYSTEM TRBH: the first patented system for the ventilation of resin transformers!

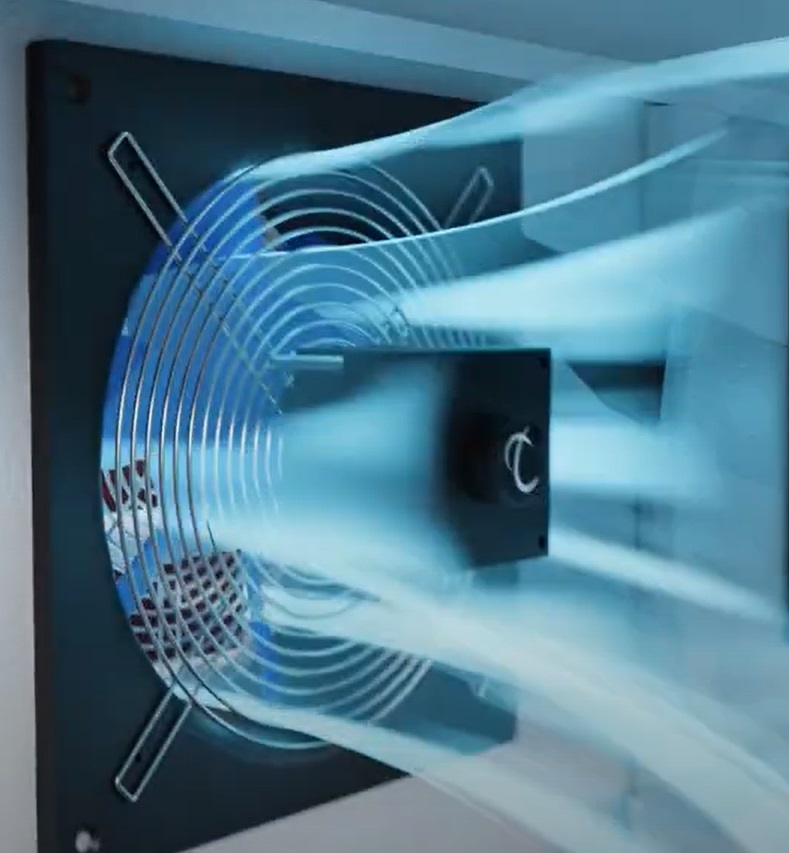

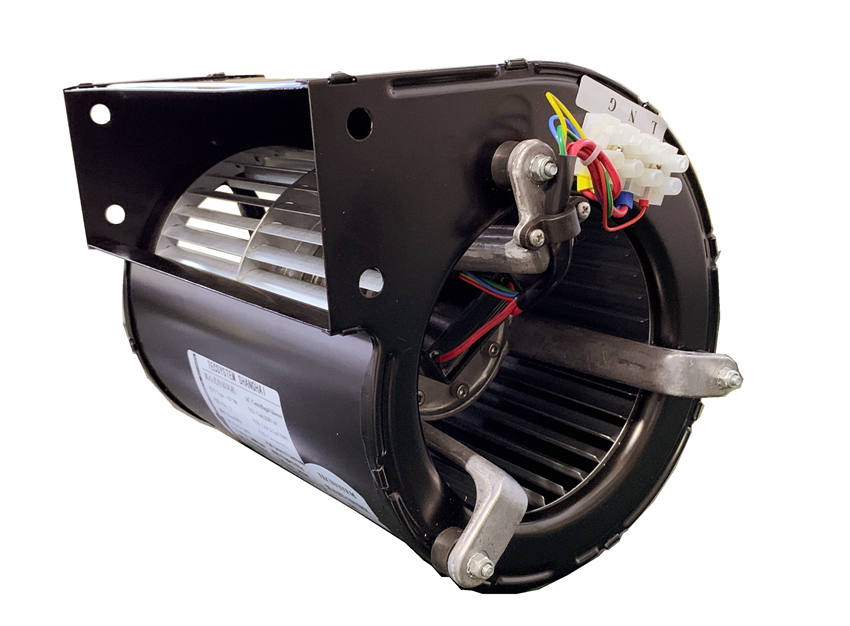

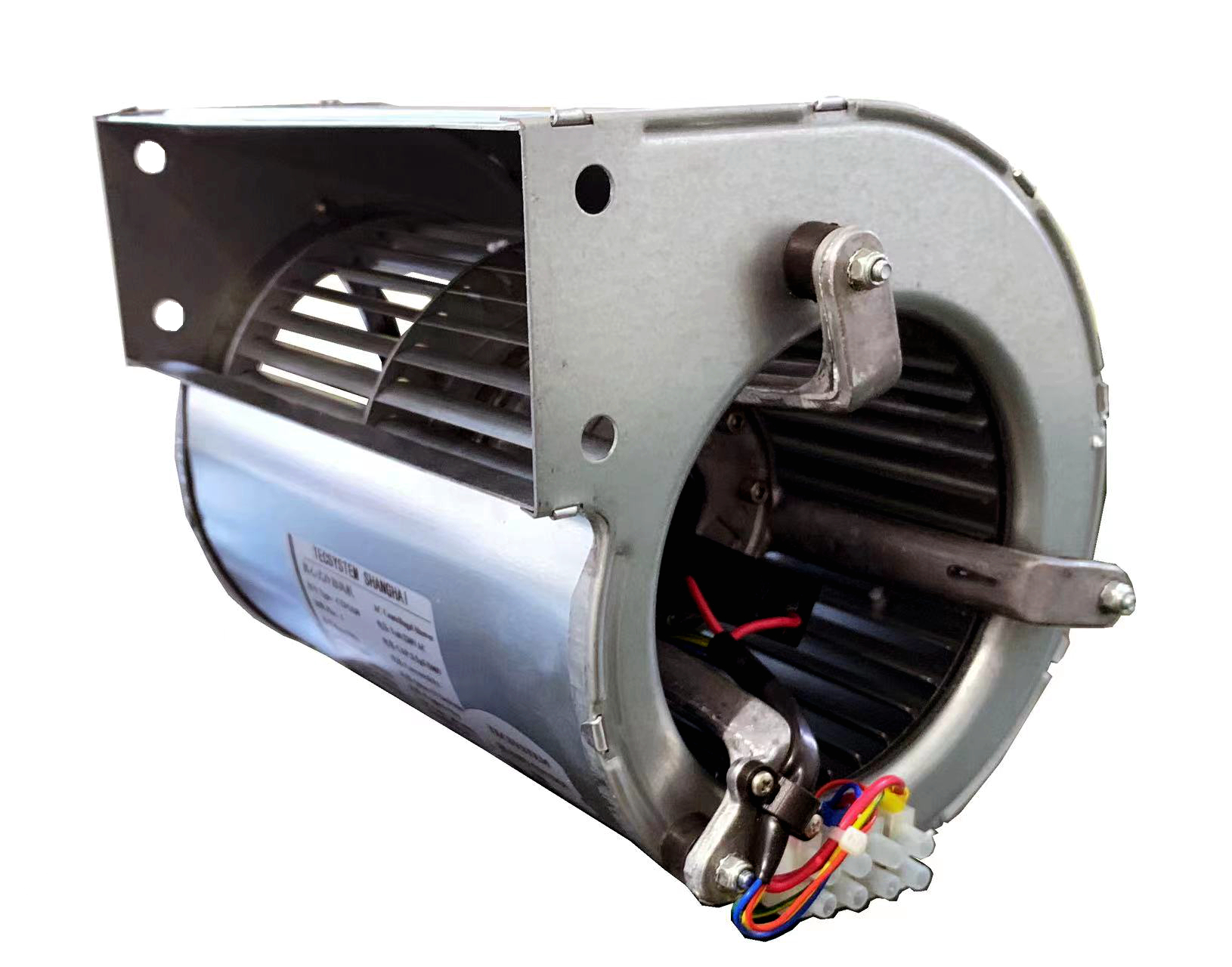

The resin transformers for the distribution of electricity during their operation produce heat. The transformer by its constructional nature dissipates the heat in the surrounding environment by thermal convection. When the environmental and load conditions are critical, the natural circulation of the air is not sufficient to ensure adequate cooling of the machine. To overcome these drawbacks Tecsystem – in the 90s – presented ventilation systems equipped with a support for quick assembly on transformers. But traditional ventilation systems have little to do with the new opportunities offered by industry 4.0 due to connectivity limitations.

The TRBH system was born on the basis of a philosophy and experience that Tecsystem has been promoting for years: from the simple optimization of interventions to the more refined concept of predictive maintenance! All this is possible thanks to the data that the system is able to provide through ETHernet or RS485 communication.

Some of the advantages of using the TRBH system:

Reduction of electricity consumption: with the revision of the Ecodesign 2009/125 / EC legislation for the reduction of transformer losses in 2021, the consumption of electrical accessories will also be included in the energy consumption counts. Tecsystem has taken this need into consideration when designing the TRBH system, obeying an increasingly restrictive regulation and ensuring lower operating costs.

Containment of the thermal and mechanical shock of the transformer: the anticipated action of heat dissipation allows you to start cooling the transformer ahead of time. The elimination of immediate ignition at maximum power allows a containment of the effects of the thermal shock which are deleterious for the mechanical structure of the transformer. The activation of the ventilation system and the adjustment of the air flow of the fans are managed directly by the thermometric control unit, which adapts the rotation speed of the pair of fans of each winding according to the temperature detected by the single Pt100. The reduction of the temperature differences between the windings allows to contain the mechanical stress due to thermal expansion and contraction.

Reduction of noise emitted by fans: The main cause of noise in a ventilation system is due to turbulence generated by the speed and pressure of the air flow. The stabilization of the operating temperature of the transformer is an important factor to consider in order to exploit it in the event of an overload.

Tecsystem: listen – realize – propose – design!

FIBER OPTICAL SYSTEM

FIBER OPTICAL SYSTEM